Laboratory muffles are essential for research and development laboratories. These robust and powerful units are essential for various processes such as drying, sterilization, sample heating and thermal analysis. Their precision and efficiency make them an indispensable investment in the scientific environment. However, they require careful handling and maintenance.

The safe use and maintenance of laboratory muffles not only extend the service life of this valuable laboratory equipment, but also ensure the reliability and quality of the test results and analyses performed. In addition, they contribute to a safe and efficient working environment.

Safe Use of Laboratory Muffles

The first step towards the safe use of laboratory muffles is the correct understanding of their applications and limitations. The muffles must be used for the process specified, as incorrect use can damage both the muffle and the quality of the results.

High temperatures inside the muffle constitute a major risk. Therefore, the user should familiarize himself with safety and emergency procedures. External parts of the muffle can reach dangerously high temperatures; therefore, it is recommended to always wear personal protective equipment when operating.

In addition, muffles should be placed in a work area free of flammable objects and there should be ample space for heat dissipation. When using hazardous chemicals, it is essential that the operation of the muffle be closely supervised to avoid accidents.

Periodic Maintenance of Laboratory Muffles

Proper maintenance is crucial to ensure long muffle life and safe, efficient operation. There should be a periodic maintenance program that includes regular cleaning, checking for damaged components and calibration.

Cleaning should be performed only when the muffles are cold. All debris should be removed and it is essential not to use water or water-based cleaning agents to avoid corrosion. Instead, cleaning agents recommended by the manufacturer should be used.

Damaged components should be detected and repaired immediately. This includes checking power cables, ventilation ducts and internal components such as the refractory muffle, heating elements and door controls.

Calibration is also essential to ensure accurate and optimal performance. Manufacturers provide specifications for calibration and it is crucial to adhere to them.

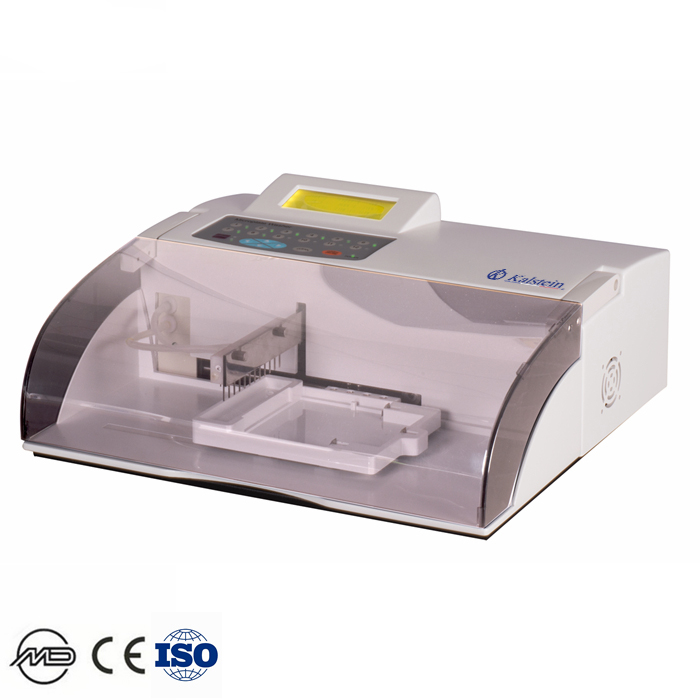

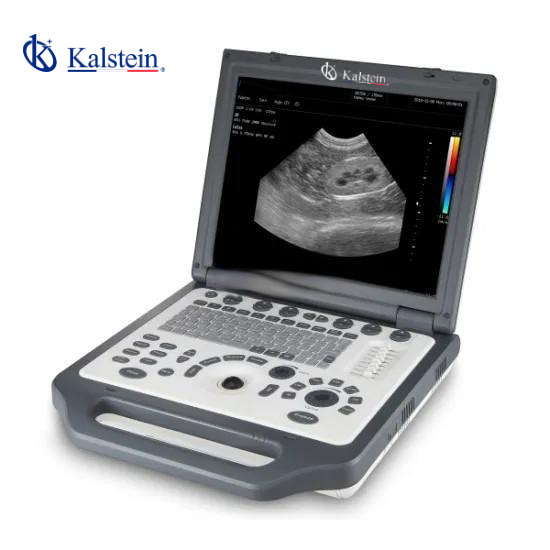

What we offer you at Kalstein

An optimal maintenance program and a thorough understanding of safe operating procedures are therefore essential for any laboratory using muffles. HERE

As a manufacturing company we have innovative designs that meet your laboratory requirements and needs; If you wish to purchase a quality stainless steel muffle furnace do not hesitate to contact us, we also assure you the best price in the market and the necessary advice for you to choose the YR model that best suits you, we know HERE.