Color evaluation boxes are intended to provide a standardized and reliable method for measuring the colors of finished products and components, thus enabling contrasts and validations of light transmittance and absorption, which are important factors in industries of all types. Many cosmetics, textile and paint companies, as well as food production and electronic device industries, use color evaluation boxes to produce high-quality products and to offer their customers consistent, safe and good-looking products.

The choice of a color evaluation box is critical for quality assurance and quality control. Industrial laboratories can rely on the use of these boxes for rigorous compliance with the procedures and parameters required of them to ensure product safety and consistency. Therefore, an industrial laboratory can benefit significantly from the guarantees offered by color evaluation boxes.

What Guarantees Do Color Evaluation Boxes Offer to Industrial Laboratories?

The use of a color evaluation box allows the industrial laboratory to establish and achieve an optimal quality level by setting unambiguous color parameters. This ensures uniformity in production, consistent reproducibility of parameters and the desired expected results. In addition, a color evaluation box is easy to set up and calibrate according to the laboratory’s preferences using professional software and control programs created specifically for this purpose. These programs make setting color parameters quick and easy.

In industrial laboratories, it is important to be able to trace products from the time they are manufactured until they reach the consumer. This means that manufacturers must establish and maintain complete and accurate records of their quality criteria and the results of products and components. A color evaluation box offers an ideal solution for the recording and traceability of finished products, as the approved results are stored and can be referred to in the future if necessary. This ensures that the production process is fully documented and verified, creating specific and detailed records.

Detailed inspection and reporting

Color evaluation boxes also enable industrial laboratories to carry out defect detection inspections efficiently and safely. These boxes provide an honest inspection of finished products and the results are recorded in customizable standardized reports for further analysis and comparison. This allows industrial laboratories to verify their products against quality standards, ensuring that there are no defects in color or overall quality before the product is shipped to the customer.

Color evaluation boxes offer several assurances to industrial laboratories, including optimal product configurations and sizing, reliable recording and traceability, detailed inspection and reporting, and other benefits that enable industrial laboratories to manufacture high quality products to meet the demands of their customers. These evaluation boxes provide a standardized procedure for measuring the colors and quality of products manufactured in industrial laboratories, allowing these products to be safe, good looking and consistent throughout each production cycle.

What Kalstein offers you

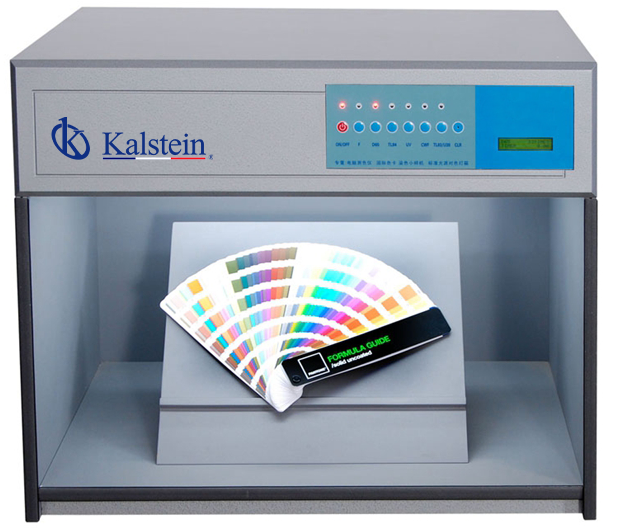

We at KALSTEIN have for you high end color evaluation boxes that will suit your laboratory needs, visit us HERE we assure you, through our online purchasing channels, reminding you that we are a manufacturer of high level laboratory equipment for sale and purchase.

Kalstein Model YR05531 Six light source light box adopts fully computer-controlled touch buttons to switch light sources at will and can permanently record each light source’s name, time of use and the number of times it is turned on. It has the function of testing the effect of metamerism. It is implemented according to international standards (ISO, ASTM, DIN, BSI, ANSI, CIE) and passes national measurement inspection with authoritative test report.