Description

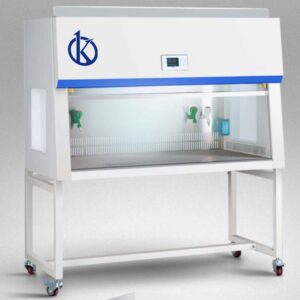

The Laminar Flow Cabinet (Single Person) YR05266-1 is an essential asset in fields such as biotechnology, pharmaceuticals, life sciences, and precision electronics. This meticulously designed YR series clean bench merges advanced airflow mechanics to establish a partially purified workspace ideal for conducting experiments efficiently. With CE certification and a generous two-year warranty, this product is as reliable as it is functional. Its user-friendly interface, featuring an integrated LCD dot matrix display, keeps the user informed about lighting, sterility levels, and airflow parameters in real-time, ensuring optimal operation conditions at all times.

Market Price

In the market for laminar flow cabinets, prices can vary significantly based on design, features, and brand reputation. For a high-quality model like the YR05266-1, prices typically range from approximately 1200 USD to 2000 USD. While the initial investment may appear substantial, the long-term benefits of ensuring precision and protection in sensitive environments can deliver excellent value.

Frequently Asked Questions

Does the YR05266-1 come with a warranty? Yes, it includes a two-year warranty to ensure peace of mind.

Is assembly required upon delivery? The cabinet is mostly pre-assembled; however, minor setup may be needed.

Does it remove airborne particles effectively? Absolutely. With its high-efficiency HEPA filter boasting a 99.99% retention rate, it ensures comprehensive air purification.

Advantages and Disadvantages

The YR05266-1 provides impeccable cleanliness with low power consumption, meeting ISO 14644.1 Class 5 standards. Its ergonomic design enhances user comfort and productivity. However, the noise level, at ≤62 dB, might be a factor to consider in overly quiet lab environments. Additionally, it requires periodic maintenance to sustain its peak performance, specifically concerning filter replacements.

Product Usage in the Field

In practical scenarios, the YR05266-1 delivers a controlled, contamination-free environment greatly beneficial in laboratories. Its vertical and horizontal airflow adjustments cater to diverse experimental needs, while ensuring safety through its interlock functions. The built-in UV protection avoids potential operator hazards, facilitating safer working conditions.

Recommendations

To maximize efficiency, it’s advisable to frequently clean or replace the filters as recommended after extensive usage periods. Utilizing the CLEANFLOW™ technology, ensure regular maintenance checks to uphold optimal airflow and reduce micro-contaminant risks.

Features

- User-friendly LCD interface for real-time monitoring

- Adjustable multi-level wind speed to cater to specific needs

- Advanced HEPA filtration to maintain 99.99% air purity

- Ergonomic design focused on user comfort

- Noiseless operation to ensure a quiet work environment

Technical Specifications

| Model | YR05266-1 |

| Cleanliness Rating | The international ISO 14644.1 standard, CLASS 5 (U.S. Federal 209E, 100 level) |

| Wind Speed | 0.3~0.6m/s (Adjustable) |

| Noise (dB) | ≤62 |

| Vibration half peak | ≤3μm (X, Y, Z direction) |

| High efficiency filter | Efficiency 99.99% |

| Illumination (LX) | ≥300 |

| Work environment | Ambient temperature 10~30℃, Relative humidity |

| below 70%, No obvious vibration and dust around | |

| Overall size (mm) (H×W×D) | 1585×990×735 |

| Inner size (mm) (H×W×D) | 500×830×550 |

| Voltage (V)/ | AC220V/50Hz |

| Power (W) | 200 |

| Net weight (KG) | 120 |

| Shipping weight (KG) | 130 |

| Packing size (mm) (H×W×D) | 1030×1180×855 |