The climatic chamber is a unit able to build the will of stable situations of temperature and relative humidity, to provide controlled climatic states, in order to have a reliable measurement pattern in the measuring instrument. It is made by an airtight structure, able to provide pressures between the inside and the outside, its main components being an access gate, means to humidify and condition the air inside the chamber, sensors and temperature controllers.

Within the commercial line, they are considered as a standard equipment to evaluate and measure the preservation of the samples, mostly used to store pharmaceutical products, veterinary, agri-food, biotechnological, biological, chemical, materials and others, under constant conditions of temperature and controlled humidity.

Types of Cameras

Occasionally, the climatic chambers can be adjusted with various systems, such as photoperiod, to perform studies of plants, vegetables, insects, etc. or photostability for pharmaceutical or cosmetic studies. However, using as an example the pharmaceutical sector, where studies of duration are very rigorous, climatic chambers are able to store products for 12 months under conditions of 25ºC +/- 2ºC of temperature and 60% +/- 5% of relative humidity.

There are also different types of cameras, which are:

- Constant climate chambers: are elements for climate assessment, where it specifies and regulates humidity conditions at constant level. Within the pharmaceutical industry, climate zone testing, long-term testing, more than 12 months and accelerated testing of more than 6 months are performed. All of these tests are used for authorization and ongoing review of drugs and their principles.

- Variable climate chambers: developed by means of homogeneous conditions, available from high climate change, to meet demanding material tests. Determines the lower and upper temperature limit of component failure, climatic range for operation, transport conditions, storage and use consistent with the provisions and hidden design defects. Tests include extreme and rapid temperature and humidity changes to cause accelerated aging until destruction.

Validation of the Climatic Chambers

Climatic chambers, which meet a goal of maintaining certain quality standards, are indispensable to check the behavior of materials in many sectors. They provide precise grounds for the efficacy of prototypes, under stipulated temperature, humidity and light contexts, which are necessary for the authorization of new products. For camera validation, the following criteria should be considered:

- Accurate temperature measurement: Conditions can only be properly assessed, under constant temperature contexts over a long period.

- Light recording and homogeneous distribution: In photostability tests, the camera should be illuminated homogeneously with a balanced ratio of UVA radiation and natural light.

- Active humidification and dehumidification: Allows greater flexibility with or without direct connection to water outlets. Also, a fast reaction time for vapor humidification is important.

- Administration: It must have standard sizes to the human, for better handling of the samples.

- Accurate calculation and logging – provides reliable results that can be easily analyzed.

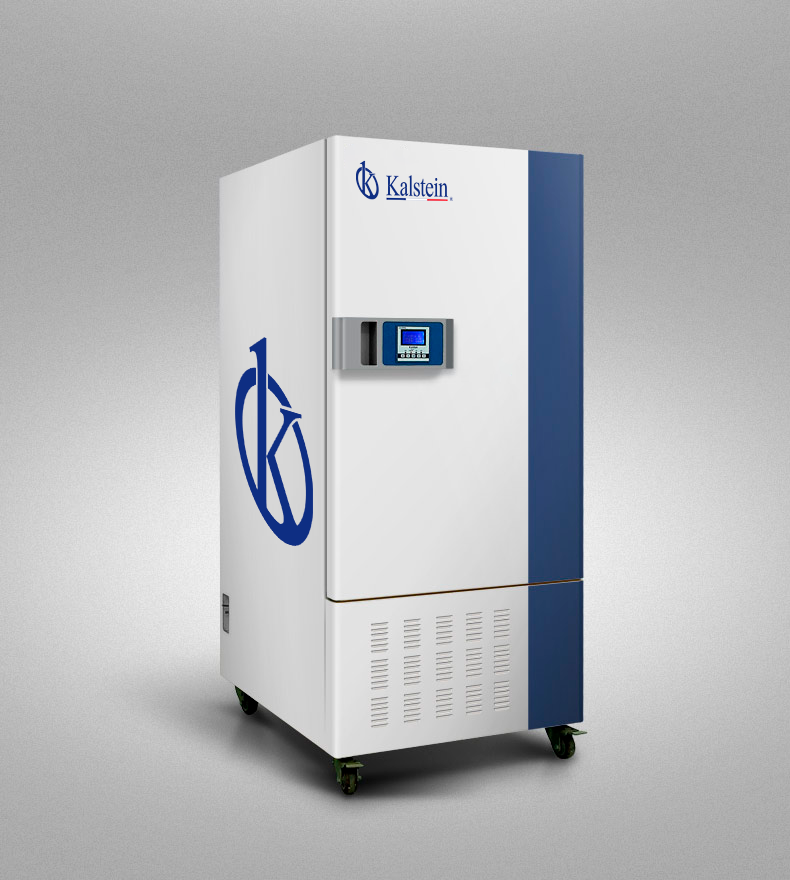

Climate Chambers in Kalstein

At Kalstein, we are trained to offer you the best medical equipment, capable of meeting all the demands of our clients. We provide you with the best technology, such as the constant climate chamber model YR, which provides all the benefits for the preservation of medicines. For this reason, our medical team has attractive features, such as: LCD screen with integrated dot matrix, Chinese and English subtitles, design for maximum operational comfort. Programmable multi-section control, to meet customer needs, temperature and humidity control up to 30 sets. Time setting: 0-99h, 0-9999m, programs can be run automatically in cycles. HERE

Set operations with sound warnings Operation by remote control, with programmable software (option). Bacteria-free culture with UV disinfection (know the mold incubator).

For more information, check out HERE